Um morango, com sua cor e textura perfeitamente preservadas, derrete na boca, replicando perfeitamente a sensação da fruta fresca—esta é a magia da tecnologia de liofilização.

Nos últimos anos, os alimentos liofilizados ocuparam silenciosamente posições de destaque nas prateleiras dos supermercados e nas plataformas de comércio eletrônico em todo o mundo. De petiscos de alta qualidade para animais de estimação a guloseimas para escritório e refeições para aventuras ao ar livre, os produtos processados usando a tecnologia de liofilização estão se integrando em nossas vidas de várias formas.

A análise de mercado mostra que o mercado global de alimentos liofilizados atingiu US$ 7,11 bilhões em 2024 e deve crescer para US$ 12 bilhões até 2035. O que exatamente está impulsionando a popularidade global dos alimentos liofilizados? A tecnologia de liofilização realmente preserva melhor os nutrientes?

Tendências de Crescimento no Mercado de Alimentos Liofilizados

O rápido crescimento do mercado de alimentos liofilizados não é acidental, mas sim o resultado de múltiplos fatores.

A busca dupla dos consumidores por saúde e conveniência é a principal força motriz. A tecnologia de liofilização maximiza a preservação de nutrientes naturais, ao mesmo tempo em que prolonga a vida útil sem a necessidade de conservantes, alinhando-se perfeitamente com os estilos de vida modernos e as tendências de saúde.

Enquanto isso, a expansão dos cenários de aplicação também chamou mais atenção para os alimentos liofilizados:

- Esportes e Viagens ao Ar Livre: Leves e com longa vida útil, os alimentos liofilizados são adequados para acampamentos, caminhadas, montanhismo e outras atividades que exigem lanches leves.

- Armazenamento de Emergência e Estocagem de Alimentos para a Família: Os alimentos liofilizados podem ser armazenados em temperatura ambiente por muitos anos, tornando-os ideais para armazenamento familiar a longo prazo.

- Consumo Aprimorado de Alimentos para Animais de Estimação: Pedacinhos de carne liofilizada e alimentos frescos liofilizados são mais populares entre os donos de animais de estimação devido à sua fonte de carne real e alto teor de proteína.

- Novos Tipos de Lanches Ganham Popularidade: Por exemplo, chips de frutas liofilizadas, cubos de iogurte liofilizados e salgadinhos de frutas e vegetais liofilizados oferecem uma textura crocante sem o ônus adicional da fritura, tornando-os populares entre os consumidores mais jovens.

Como pode ser visto, seja conveniência, saúde, nutrição, portabilidade ou os atributos experienciais "novos e deliciosos", os alimentos liofilizados ressoaram com sucesso com o estilo de vida atual e criaram um boom de mercado.

O que é a Tecnologia de Liofilização?

A liofilização é uma tecnologia avançada de desidratação amplamente utilizada na conservação e processamento de alimentos. Seu princípio básico é primeiro congelar rapidamente o alimento em baixas temperaturas e, em seguida, sublimar o gelo diretamente em vapor d'água sob vácuo, alcançando assim a desidratação. Todo o processo é realizado em baixas temperaturas, evitando efetivamente danos causados pelo calor e maximizando a preservação da forma, cor, sabor e componentes nutricionais do alimento.

Em outras palavras, usar um liofilizador para processar alimentos não é sobre "cozinhar" ou "secar", mas sim sobre converter diretamente a água do estado sólido para o gasoso, com quase nenhum dano à estrutura do alimento.

O processo principal da tecnologia de liofilização: Congelamento em baixa temperatura → Desidratação a vácuo (sublimação) → Remoção de umidade → Preservação da forma intacta

Liofilização vs. Outros Métodos de Secagem

| Método de Secagem |

Temperatura |

Retenção de Nutrientes |

Textura |

Vida Útil |

Principais Características |

| Secagem ao Ar |

Temperatura ambiente |

Baixa |

Dura, perda de sabor |

Moderada |

Baixo custo, perda significativa de nutrientes |

| Ar Quente / Secagem em Forno |

Alta temperatura |

Perda significativa de nutrientes |

Textura e cor alteradas |

Curta |

Comum para lanches e especiarias baratos |

| Liofilização |

Sublimação em baixa temperatura |

Alta retenção de nutrientes |

Forma intacta, excelente reidratação |

Mais longa |

Processamento de alimentos de alta qualidade, ideal para alimentos saudáveis |

Como mostra a tabela, a liofilização oferece claras vantagens na retenção de nutrientes, textura, aparência e vida útil, o que explica por que os liofilizadores de alimentos se tornaram cada vez mais populares na indústria.

Por que os Fabricantes de Alimentos e Restaurantes Estão Adotando Liofilizadores?

1. Maior Competitividade do Produto: A tecnologia de liofilização permite que os produtos obtenham um rótulo de saúde "natural, sem aditivos e que preserva nutrientes", alinhando-se melhor com as tendências atuais dos consumidores.

2. Vida Útil Prolongada e Custos de Logística Reduzidos: Os alimentos liofilizados têm baixo teor de umidade, permitindo o armazenamento a longo prazo em temperatura ambiente e tornando o transporte mais fácil e reduzindo os custos.

3. Sabor e Experiência do Produto Aprimorados: Em comparação com a secagem tradicional, os alimentos liofilizados, após a reidratação, têm um sabor e aroma mais próximos dos ingredientes originais, aprimorando a reputação da marca e aumentando as taxas de recompra.

4. Adaptabilidade para o Desenvolvimento de Alimentos de Alto Valor e Inovadores: Exemplos incluem frutas liofilizadas, refeições prontas para consumo liofilizadas, pó de café, coalhada de leite, carne liofilizada para animais de estimação e lanches saudáveis.

Portanto, os liofilizadores estão se tornando uma peça central do equipamento de produção em empresas de fabricação de alimentos, redes de restaurantes, fábricas de refeições prontas para consumo e novas marcas de lanches.

Os Alimentos Liofilizados Têm Maior Valor Nutricional?

Muitos consumidores preferem alimentos liofilizados principalmente por causa de sua alta retenção de nutrientes e da natureza limpa e sem aditivos de seus ingredientes. Em comparação com os processos tradicionais de secagem ou desidratação em alta temperatura, a liofilização remove a umidade em um ambiente de baixa temperatura e vácuo, evitando efetivamente a destruição de nutrientes sensíveis ao calor.

1. Processo em Baixa Temperatura Preserva Eficazmente os Nutrientes

Durante todo o processo de liofilização, os alimentos permanecem em baixas temperaturas, o que impede a desnaturação de proteínas, a decomposição de vitaminas e a perda de antioxidantes. Testes da indústria mostram que em alimentos liofilizados:

- A retenção de vitaminas pode exceder 90%

- As estruturas proteicas permanecem estáveis

- Minerais e fibras alimentares são quase completamente preservados

Por exemplo, a papaia liofilizada, sem quaisquer conservantes adicionados, mostra excelentes resultados no teor total de fenólicos, nos níveis de carotenoides e na atividade antioxidante geral. Estudos também indicam que a liofilização pode manter as antocianinas abaixo de 40°C e os carotenoides abaixo de 60°C, protegendo esses nutrientes da degradação pelo calor. Como resultado, os alimentos liofilizados podem preservar com mais fidelidade o valor nutricional dos ingredientes originais.

2. Estrutura Celular Intacta: Sabor e Textura Mais Próximos dos Alimentos Frescos

Como a água sublima diretamente do gelo sólido para o vapor, a estrutura celular do alimento é amplamente preservada. Isso permite que os alimentos liofilizados:

- Mantenham sua forma original

- Mantenham uma textura crocante ou macia

- Reidratem rapidamente para quase a textura e o sabor originais

Em comparação com os alimentos secos em alta temperatura, os produtos liofilizados se assemelham mais aos ingredientes frescos em cor, textura e sabor. A estrutura porosa e esponjosa formada durante o processo impede a contração comum na desidratação convencional, dando aos alimentos liofilizados um excelente desempenho de reidratação.

3. Armazenamento a Longo Prazo Sem Conservantes

Os alimentos liofilizados normalmente contêm apenas 1%–5% de umidade, o que inibe o crescimento microbiano e permite o armazenamento natural a longo prazo. Isso oferece várias vantagens:

- Sem necessidade de conservantes

- Sem adição de aromatizantes ou corantes

- Mais produtos podem ser apresentados como ingredientes puros e sem aditivos

Além disso, a otimização do processo pode enriquecer minerais específicos. Por exemplo, estudos mostram que as maçãs liofilizadas podem conter níveis de cálcio tão altos quanto 2209,13 mg/100g, mantendo alta atividade antioxidante.

No geral, os alimentos liofilizados têm claras vantagens na retenção de nutrientes. O cerne da tecnologia reside no processamento em baixa temperatura e vácuo, que minimiza a perda de nutrientes sensíveis ao calor. Os alimentos liofilizados são especialmente adequados para consumidores preocupados com a saúde que buscam lanches limpos, sem aditivos e ricos em nutrientes.

Amplas Aplicações da Tecnologia de Liofilização

Com o desenvolvimento da tecnologia de liofilização, as aplicações de liofilizadores de alimentos e liofilizadores industriais se expandiram para cobrir todos os níveis, de casa à produção em larga escala, e não se limitam mais ao processamento tradicional de alimentos.

1. Processamento de Alimentos em Casa

Liofilização de Frutas e Vegetais: Liofilizadores domésticos podem processar frutas e vegetais frescos em lanches ou pós, tornando-os fáceis de armazenar e consumir diariamente.

Suplementos para Alimentos para Bebês: A tecnologia de liofilização retém os componentes nutricionais de frutas e vegetais, tornando conveniente para os pais prepararem alimentos para bebês saudáveis e sem aditivos.

Petiscos para Animais de Estimação: Liofilizadores domésticos também são comumente usados para fazer carne liofilizada ou petiscos de frutas e vegetais liofilizados, preservando proteínas e sabor natural, que são muito populares entre os donos de animais de estimação.

2. Pequenas Fábricas de Alimentos e Microempreendedores

Para empreendedores e pequenas empresas de processamento, os liofilizadores de alimentos oferecem a possibilidade de desenvolvimento de produtos de baixo custo e alto valor agregado.

Eles podem produzir lanches emergentes, como chips de frutas liofilizadas, cubos de iogurte liofilizados e café liofilizado, atendendo à demanda do mercado por alimentos saudáveis, portáteis e inovadores.

3. Linhas de Produção da Indústria Alimentícia em Larga Escala

Os liofilizadores industriais são adequados para linhas de produção de alto volume, permitindo o controle estável da temperatura, níveis de vácuo e produção programada para garantir a qualidade consistente do produto.

A tecnologia de liofilização também está ganhando popularidade nas indústrias de carne, laticínios e alimentos funcionais, fornecendo às empresas soluções para prolongar a vida útil e aumentar o valor agregado do produto.

4. Áreas Farmacêuticas e Cosméticas

A tecnologia de liofilização também é aplicada a preparações farmacêuticas, preservação de vacinas, estabilização de ingredientes ativos e preservação a longo prazo de pós de essência ou extratos de plantas em cosméticos.

Como Escolher o Liofilizador Certo para Você

Ao selecionar um liofilizador, diante de inúmeros modelos e marcas, como você pode tomar uma decisão informada? Não se preocupe—compreender os seguintes parâmetros principais o ajudará a encontrar claramente o dispositivo que corresponde perfeitamente às suas necessidades.

Clarifique seu cenário de aplicação principal:

Liofilizador Doméstico vs. Liofilizador Comercial vs. Liofilizador Industrial

| Tipo |

Cenários de Aplicação |

Capacidade |

Características |

Vantagens |

| Liofilizador Doméstico |

Cozinha doméstica, lanches caseiros em pequena escala |

2–10 L |

Operação simples, suporta vários alimentos |

Baixo custo, conveniente, ideal para experimentação e pequenos lotes |

| Liofilizador Comercial |

Pequenas fábricas de alimentos, catering, empreendedores |

20–100 L |

Controle automatizado, produção em lote |

Eficiente e estável, produção moderada, econômico |

| Liofilizador Industrial |

Produção de alimentos em larga escala, produtos farmacêuticos, alimentos funcionais |

200 L+ |

Altamente automatizado, programável, monitoramento remoto |

Alta produção, qualidade consistente, soluções de linha de produção personalizáveis |

Quatro Parâmetros Chave para Selecionar um Liofilizador:

Capacidade da Câmara: Isso determina diretamente sua produção por lote único. Não olhe apenas para as dimensões externas—preste muita atenção à área efetiva da bandeja e ao número de camadas. Uma dica prática: escolha a capacidade apropriada com base no volume de seus ingredientes pré-processados comumente usados e considere uma capacidade adicional de 20% para crescimento futuro.

Sistema de Refrigeração: Este é o "coração" do efeito de liofilização. A temperatura e a eficiência da refrigeração são cruciais. Temperaturas mais baixas (por exemplo, -40°C a -50°C ou até mais baixas) significam que o sistema pode lidar com mais tipos de materiais, com melhor fixação de cristais de gelo e maior qualidade após a secagem. Um sistema de refrigeração eficiente também pode encurtar significativamente o tempo total do ciclo.

Eficiência da Bomba de Vácuo: Este é o "motor" do processo de liofilização. Uma bomba de vácuo potente e rápida pode reduzir rapidamente a pressão da câmara abaixo do ponto de gelo, permitindo a sublimação rápida. Isso não apenas afeta a eficiência, mas também determina se o produto final mantém sua forma perfeita e estrutura porosa.

Sistema de Controle Automático: Isso determina a facilidade de operação e a repetibilidade do processo. Um excelente sistema de controle pode concluir todo o processo—de refrigeração e bombeamento a vácuo a aquecimento e remoção de umidade—com o toque de um botão. Ele registra com precisão a curva do processo, garantindo qualidade consistente para cada lote e reduzindo muito as variáveis e o limite de habilidade associados à operação manual.

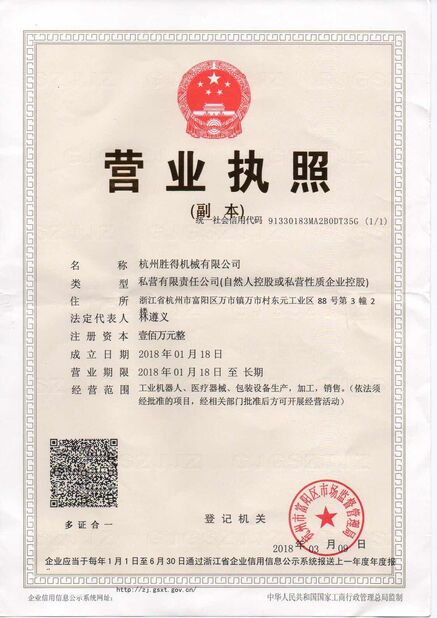

Como fornecedor líder de máquinas farmacêuticas e de embalagem, Hangzhou Shengde Machinery Co., Ltd. tem vasta experiência na venda e aplicação de liofilizadores. Podemos fornecer aos clientes aconselhamento de seleção para liofilizadores de várias especificações, cobrindo modelos domésticos, comerciais e industriais, ajudando você a escolher o equipamento de liofilização mais econômico com base em suas necessidades de capacidade de produção e orçamento.

Para obter informações mais detalhadas, entre em contato com nossa equipe de especialistas para orientação profissional e soluções personalizadas de seleção de equipamentos.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!